U.S. Glass Recycling Challenges

Glass is endlessly recyclable; manufacturers can remelt and reform it repeatedly without any loss of quality, making it an ideal material for circular use. It can also be processed into sand for reuse in other applications. Yet in the U.S., only about 33% of glass containers are recycled, compared to 70–90% in many European countries. According to 2018 EPA data, of the 12.3 million tons of glass generated, 9.2 million tons were not recycled—more than twice the amount that was recycled.

One of the largest barriers to effective glass recycling is how municipalities collect it. Single-stream systems—where glass is mixed with plastic, cardboard, and metals—are convenient for consumers but introduce major contamination issues. Contaminants are introduced via “wish-cycling,” when a user places an item into the recycling bin without understanding if it can or will be properly recycled. In single-stream systems this might include grease-soaked pizza boxes, coffee pods, and glass covered in chemical waste.

Additionally, glass in single-stream containers often breaks during collection or transit, causing it to mix with paper, plastic, and food waste, which makes it more difficult and expensive to sort and process. As a result, less than half of the glass collected via single stream is recycled into new products; the rest is downcycled, discarded as residue, or landfilled.

The highest-value use for recovered glass is closed-loop recycling back into new bottles and jars. Demand from U.S. glass manufacturers for clean cullet consistently outstrips supply, with some facilities even importing material to meet production needs. Prioritizing this bottle-to-bottle pathway delivers the greatest environmental and economic benefit, reducing the need for virgin raw materials and cutting furnace energy use. Where distance to a bottling plant makes hauling uneconomical, local processing into secondary products provides a practical alternative that still ensures glass remains in productive circulation.

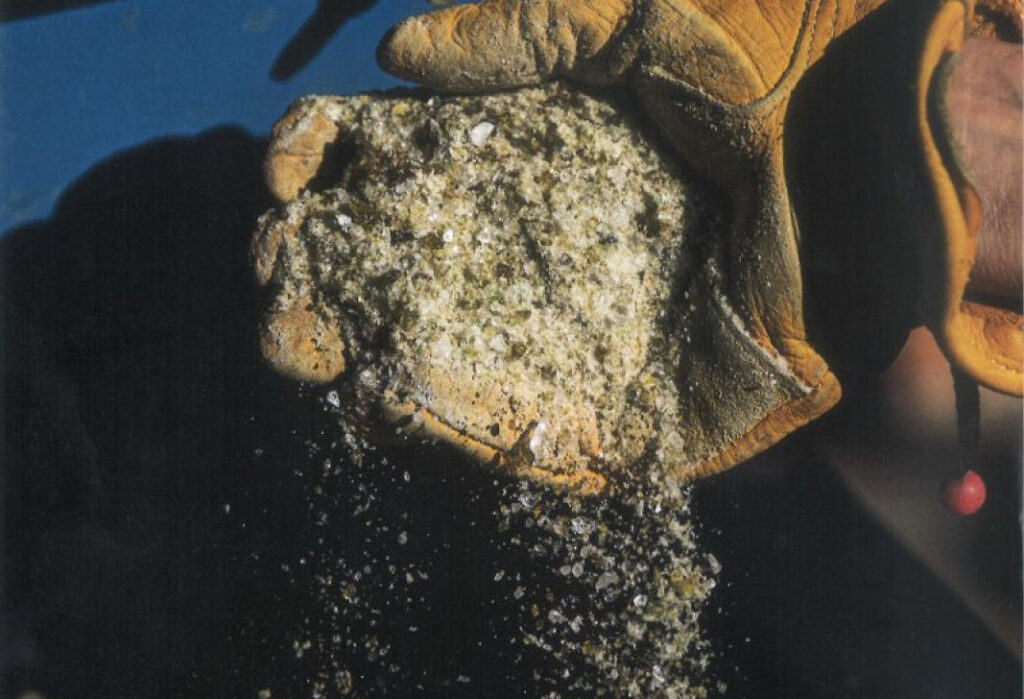

For communities where single stream is not practical, or where recycling infrastructure is limited, localized innovation can step in. One standout example is Andela Products, whose Glass Pulverizer Systems convert mixed and unsorted glass into clean sand and cullet. These materials can be used in construction, landscaping, water filtration, soil improvement, manufacturing, and abrasives. By reducing transport costs and emissions while producing a valuable secondary product, Andela’s pulverizers enable municipalities and institutions to close the loop locally.

Separating glass at the point of disposal dramatically improves capture rates, with efficiencies reaching up to 90%. In practice, this often means cleaner glass streams that go directly to cullet processors, by passing the contamination challenges of single stream.

Purpose-designed collection units, such as those using smart access controls like metroKEY, help prevent misuse, illegal dumping, and cross-contamination. This increases accountability and ensures cleaner, higher-value glass recovery.

States with bottle deposit laws consistently achieve recovery rates of 90% or more, far exceeding the national average. Expanding these programs beyond beverage containers could further boost glass capture and quality.

While the challenges facing glass recycling in the U.S. are complex, the solutions are increasingly clear: improving capture at the source through multi-stream systems, reducing contamination through secure infrastructure, deploying local glass-to-sand technologies, and incentivizing participation via deposit return schemes—all effective, scalable approaches.

metroSTOR’s role in delivering contamination-resistant, purpose-designed collection infrastructure ensures municipalities, housing providers, and institutions can capture cleaner glass streams. Localized processing technologies such as Andela’s pulverizing systems can then convert glass into usable secondary products—from construction materials and landscaping aggregates to filtration media, soil amendments, and remanufacturing feedstock.

Together, these approaches enable communities not only to collect glass more effectively, but also to transform it into valuable resources locally. With coordinated action across policy, infrastructure, and public engagement—and with proven partners like metroSTOR and Andela Products—the U.S., and other regions with similar barriers, can close the gap with Europe and realize the full environmental and economic potential of glass recycling.